Air blown fiber Cable ABF

- Being blown into place, rather than pulled

- The micro product can be reused for fiber expansion or replacement

- Cost savings

- Lead time: 5 days

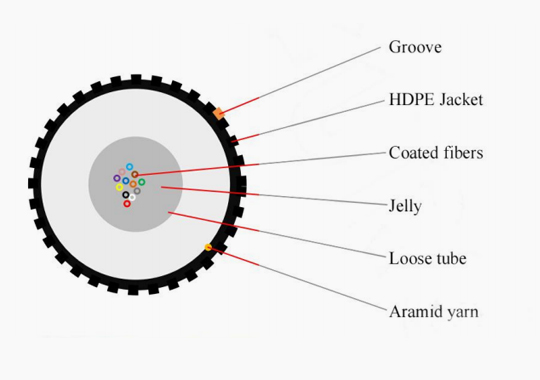

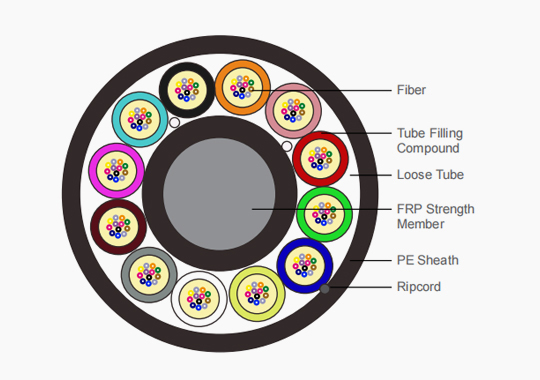

Air blowing fiber, also known as jet fiber, is an efficient way to install fiber optic cable and facilitates the future expansion of fiber optic networks. The structure of this cable is put 250µm single-mode or multi-mode optical fiber into a loose tube, the loose tube is made of high modulus material, which is filled with non-toxic and harmless waterproof compounds. The FRP strength member is put in the central tube to strengthen the cable. Outside of the loose tube is with Ripcord and polyethylene (HDPE) sheath.

Features and Benefits:

- The unique second coating and stranding technology provide the fibers with enough space and bending

- Endurance, which ensure good optical property of the fibers in the cable

- Accurate process control ensures good mechanical and temperature performance

- High quality raw material guarantees the long service life of cable

Application

Parameter of Air Blown Fiber ABF

| Item | Contents | Value | ||||||||

| 12 | 24 | 48 | 72 | 96 | 144 | 192 | 216 | 288 | ||

| Loose tube | Number | 1 | 2 | 4 | 6 | 8 | 12 | 16 | 18 | 24 |

| Outer diameter

(±0. 1mm) |

1.2 | |||||||||

| Filler | Number | 5 | 4 | 2 | 0 | 0 | 0 | 3+1 | 1+1 | 0 |

| Fiber counts per tube | G.657A1 200um | 12 | ||||||||

| Central strength member | Material | FRP | ||||||||

| Diameter (mm) | 1.2 | 2.0 | 2.4 | 1.8 | 2.4 | |||||

| Diameter of PE layer | / | / | 3.6 | / | / | |||||

| Outer sheath | Material | HDPE | ||||||||

| Color | Black | |||||||||

| Thickness (mm) | Approx.0.45 | |||||||||

| Cable diameter (±0.3mm) | 4.5 | 5.3 | 6.9 | 7.5 | 8.0 | |||||

| Cable weight (kg/km) Approx. | 18 | 26 | 43 | 48 | 58 | |||||

| For micro–duct inside (mm) | 6~8 | 8~10 | 10~14 | |||||||

| Max. tensile strength (N) | 200 | 800 | 1000 | 800 | 1000 | |||||

| Crush (N/100mm) | Short term: 500 Long term: 200 | |||||||||

Fiber Optic

Fiber Optic

Cable

Cable

Connectivity

Connectivity

PLC & WDM

PLC & WDM

Component

Component

Cable Management

Cable Management

Accessories

Accessories

Datasheet

Datasheet