Super Mini Uni-tube Blown Cable GCYFXY

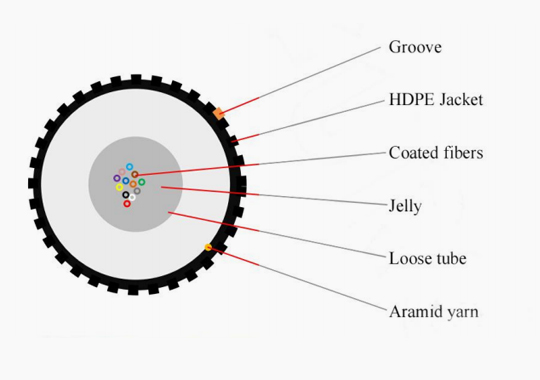

- Light weight and small outer diameter

- Non-metallic construction

- Air-blown laying

- PBT/PC material loose tube

- HDPE jacket material enhancing the blowing performance

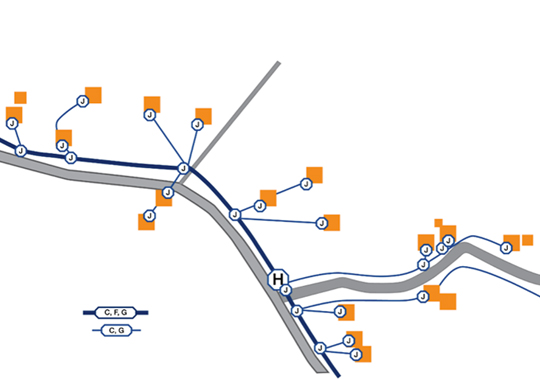

Air blown micro fiber optic cable technology is a technology that minimizes the size of fiber optic cables and pipes by optimizing materials, processes and structures, and maximizes the use of pipe space by laying them through the air blowing method. In addition to the single structure with a maximum number of 24 cores, another multi-subunit structure of air-blown fiber optic cables is available with a maximum number of 288 cores. Air blown miniature fiber optic cables are used in combination with miniature tubes (microtubes), which can accommodate five microtubes with specifications of 10/8 (OD/ID, unit mm) in an ordinary 40/33 female tube, thus fully improving the efficiency of tube hole utilization.

Features and Benefits:

- Light weight and small outer diameter

- Non-metallic construction

- Air-blown laying

- PBT/PC material loose tube

- HDPE jacket material enhancing the blowing performance

Application

Parameter of Air blown optic cable

| Items | Unit | Specification | ||

| Fiber Type | G652D/G657A1/G657A2/OM1/OM2 | |||

| Fiber Count | 2~4 | 6~12 | 14~24 | |

| Cable Diameter | mm | 2.3±0.1 | 2.5±0.1 | 2.8±0.1 |

| Duct Type | mm | 3.5/5.0 | ||

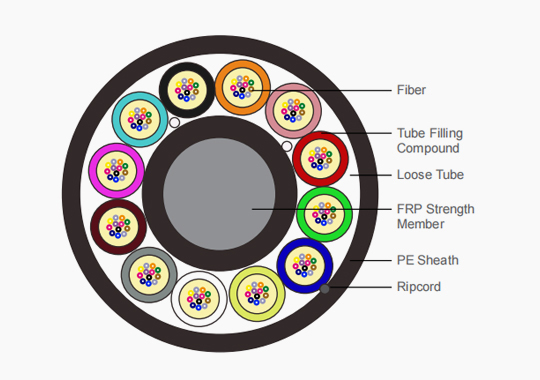

| Coating optic fiber | Dimension(μm) | 255+5μm | ||

| Material | Printing ink | |||

| Loose tube | Material | PBT/PC | ||

| Filling materials | Thixotropic jelly | |||

| Outer sheath | Material | HDPE | ||

| Tension | Long term(N) | 30 | ||

| Short term(N) | 60 | |||

| Crush | Long term(N/10cm) | 300 | ||

| Short term(N/10cm) | 600 | |||

| Min. Bend Radius (Dynamic) | mm | 20D | ||

| Min. Bend Radius (Static ) | mm | 10D | ||

| Operating Temperature | ℃ | -30~+50 | ||

| Storage Temperature | ℃ | -20~+50 | ||

Fiber Optic

Fiber Optic

Cable

Cable

Connectivity

Connectivity

PLC & WDM

PLC & WDM

Component

Component

Cable Management

Cable Management

Accessories

Accessories

Datasheet

Datasheet