Splitter is a passive optical device that can split an input optical signal into multiple output optical signals. It is widely used in passive fiber optic networks. According to different working principles, optical splitters are divided into PLC (fused biconical taper splitter) and FBT (planar lightwave circuit splitter). Do you know the difference between them? After reading this article, you will have a clearer understanding of them.

What is PLC ?

PLC is manufactured using semiconductor technology and can provide a good solution for larger split configuration applications. PLC is a waveguide fabricated on a quartz glass substrate through photolithography technology, so that it can route a specific percentage (equal ratio) of light. Usually, the optical splitting ratio of PLC is 1:4/1:8/1:16/1:32/1:64. There are bare fiber PLC, micro steel tube PLC, ABS box PLC , insert type PLC , rack-mounted PLC and so on.

What is FBT ?

FBT uses traditional passive device manufacturing technology to bundle two or more fibers together and achieve melt drawing through a tapering machine. Because the fused optical fiber is relatively fragile, a glass tube made of epoxy resin and silica is usually placed outside the fused optical fiber. At the same time, a layer of stainless steel tube is placed outside the glass tube, and finally silicone is used for sealing. With the maturity and development of technology, FBT is becoming more and more cost-effective.

PLC vs FBT : What’s the difference?

It can be seen from the above that the manufacturing processes of PLC and FBT are different. In addition, these two optical splitters also have the following differences:

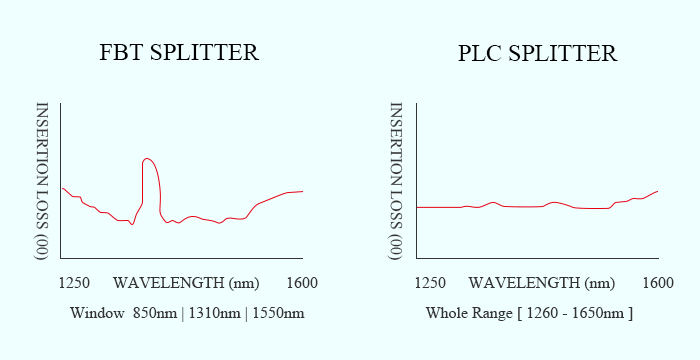

Working Wavelength

The working wavelength of the PLC is between 1260nm and 1650nm. The wavelength is adjustable and supports more application environments. The FBT only supports three wavelengths: 850nm/1310nm/1550nm and cannot work at other wavelengths. .

Splitting Ratio

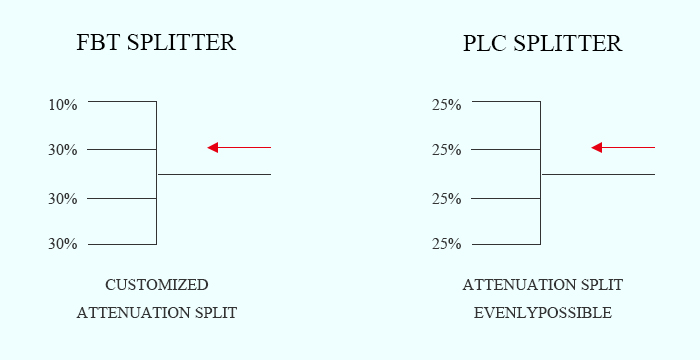

The splitting ratio refers to the ratio of the input optical signal and the output optical signal of the optical splitter. The PLC split ratio is as high as 1:64, while FBT split ratio is 1:32. Relatively speaking, PLC can provide higher reliability. However, FBT’s optical split ratio is variable and supports customization, such as 1:3, 1:7, and 1:11, while the PLC can only select 1:2 , 1:4, 1:8, 1:16, 1:32, 1:64 standard products.

Spectral Uniformity

PLC can achieve uniform light splitting in equal proportions, while FBT is packaged by multiple 1×2 connections. It lacks signal management and cannot achieve uniform light splitting. Moreover, the larger the light splitting ratio, the worse the uniformity, which affects transmission distance.

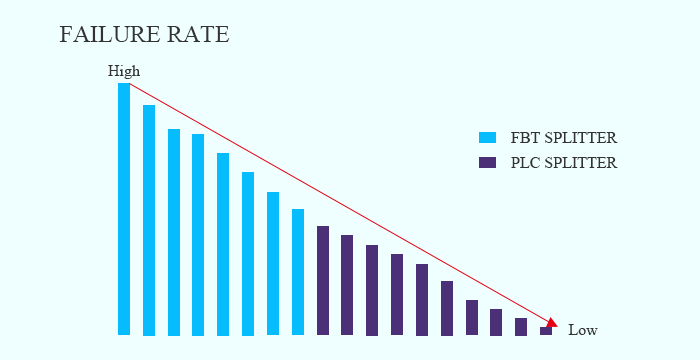

Fault Rate

At present, the mature tapering process can only draw less than 1×4 at a time. Therefore, when the splitting ratio is greater than 1:8, the FBT requires more than 7 1×2 connection packages. At this time, errors are prone to occur, leading to failures. In other words, the greater the FBT splitting ratio, the greater the failure rate. The failure rate of PLC is much smaller than that of FBT , as shown in the figure below.

Temperature

Temperature is a key factor affecting the insertion loss of optical devices. Therefore, temperature stability plays a vital role in the performance of the device. PLC can work stably at -40~85℃, while the operating temperature range of FBT is -5~75℃. Relatively speaking, PLC has a wider operating temperature range, and in extreme cases it also maintains good performance in the environment.

Cost

PLC has complex manufacturing processes and high chip costs; FBT is made of steel, heat shrink tubes and other materials. Since the material cost is not high and the device manufacturing technology is simple, relatively speaking, FBT is cheaper.

In general, in addition to similar appearance and size, PLC and FBT have many differences in manufacturing processes, operating wavelengths, temperatures, etc. It can be seen from the advent of PLC that the manufacturing technology of optical splitters has made great progress in recent years. Compared to the traditional FBT , the PLC is a passive type with superior performance. Optical components, if your network has high performance, it is recommended that you choose PLC instead of FBT.